Final Product and Prototypes:

Click through to look at the images closely.

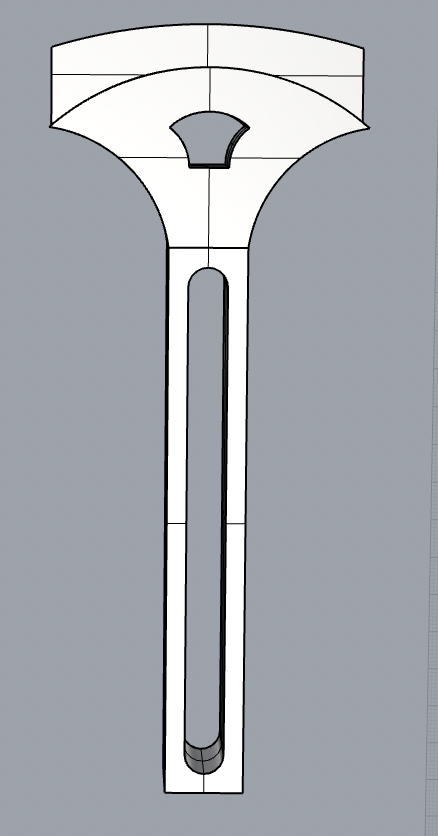

Finished Product

Side View

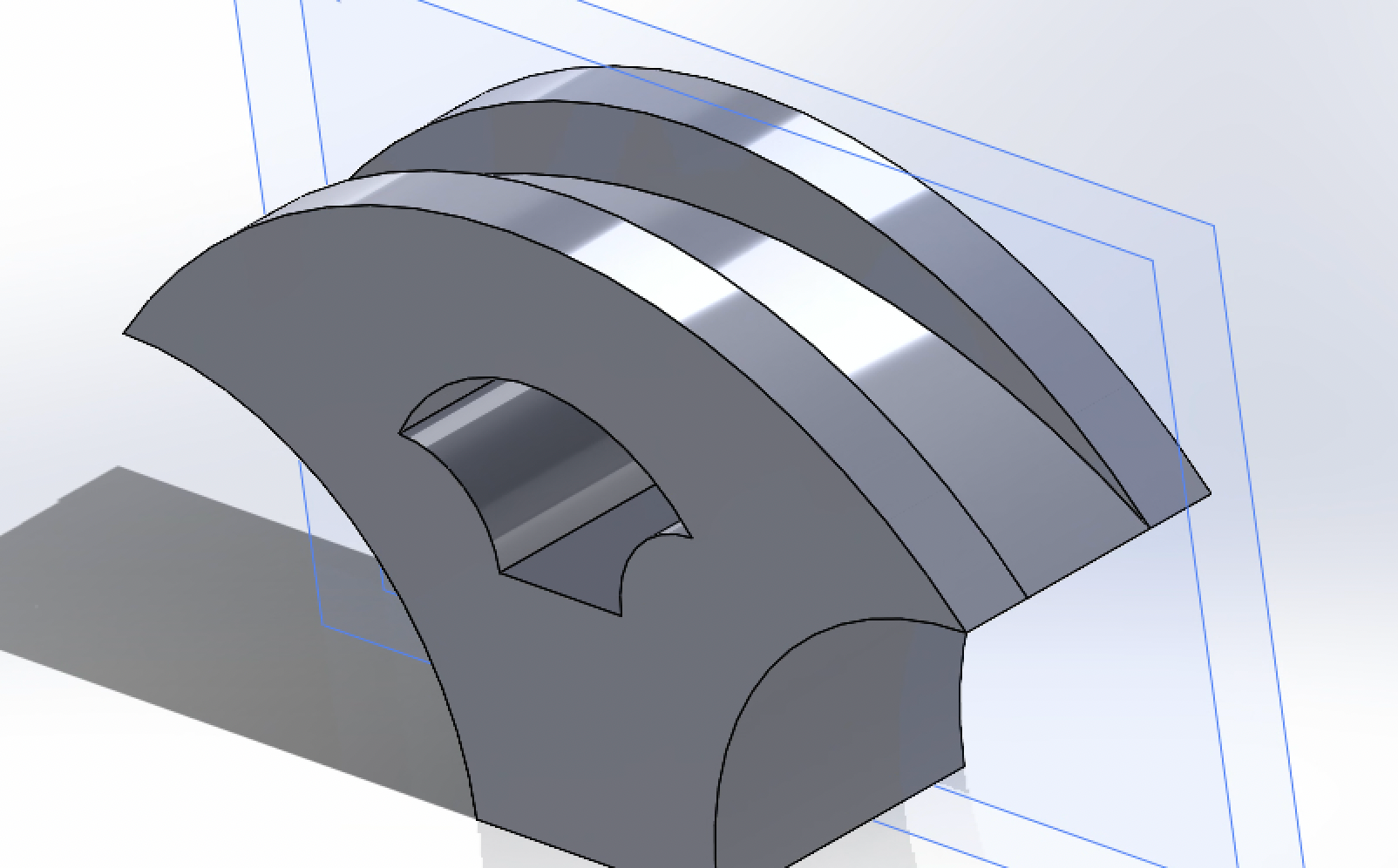

SolidWork Prototype 2

SolidWorks Prototype 2

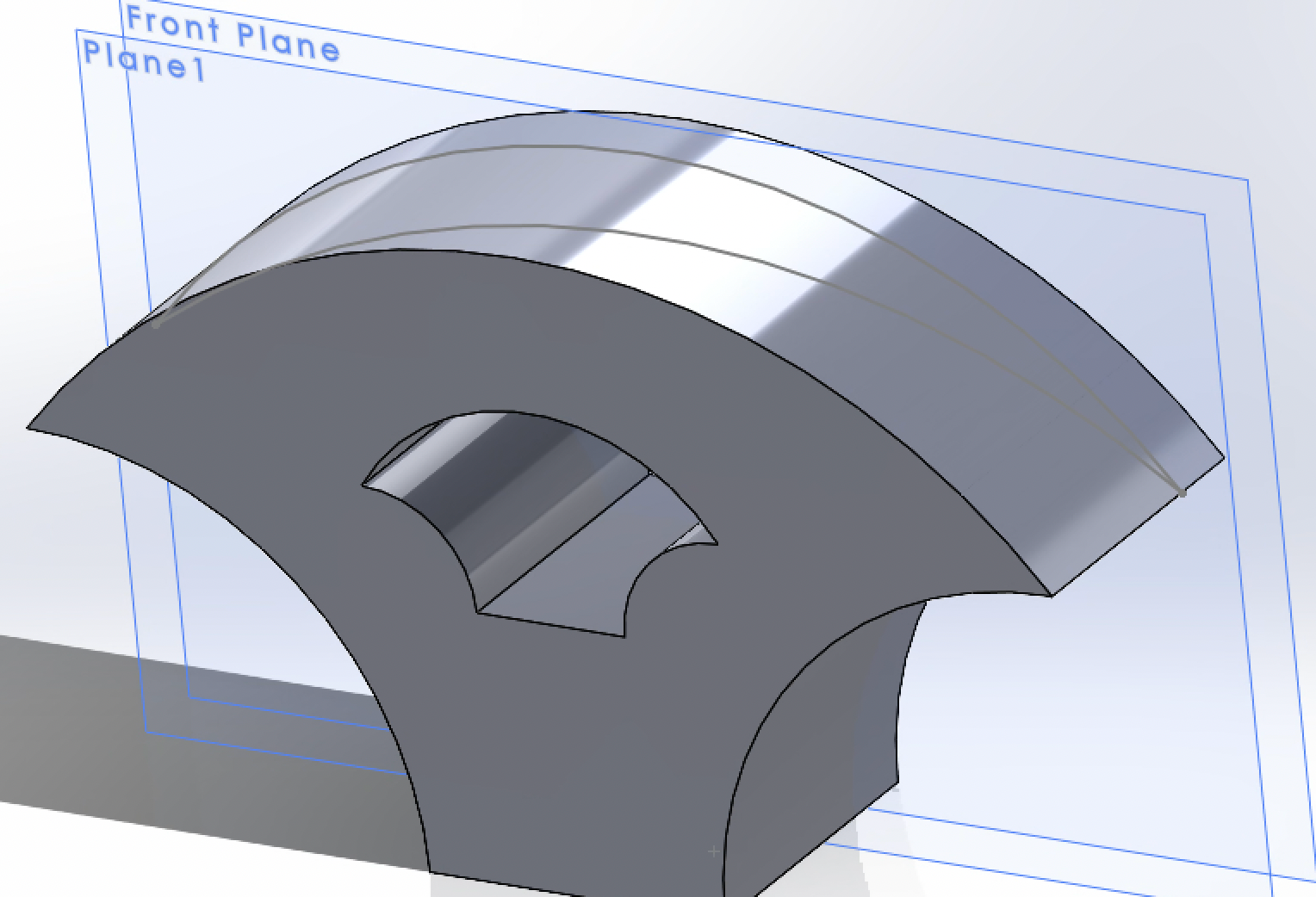

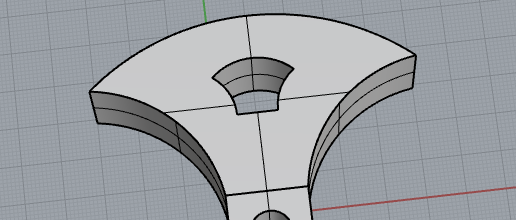

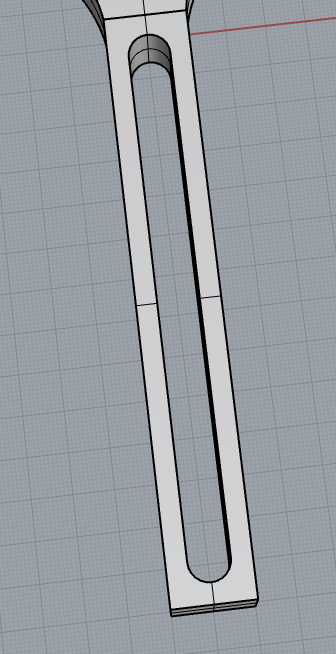

Rhino 7 Prototype 3

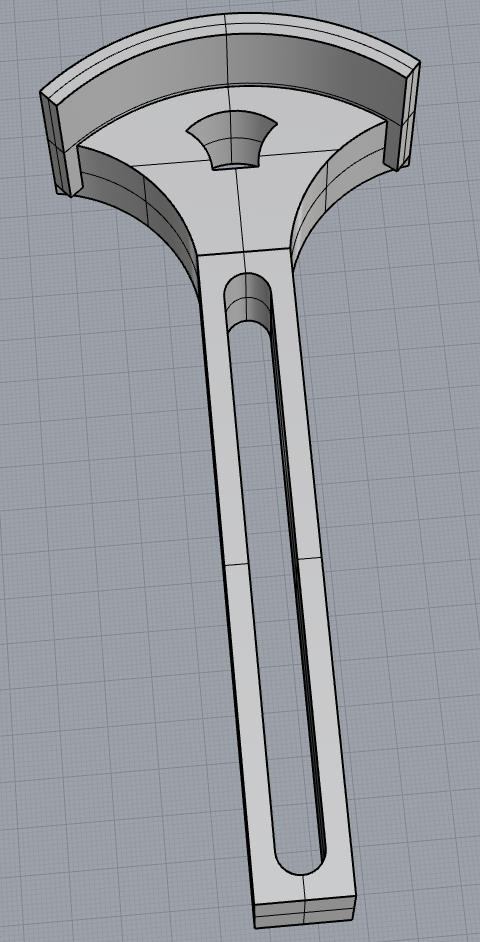

Rhino 7 Final Prototype

Conversion from SolidWorks to Rhino 7

Headphone Stand

Designing a Practical 3D-Printed Object with Time Constraints

For the second project in my Form and Structure course at Northeastern University, I was tasked with creating a practical 3D-printed object using modeling software like Rhino 7 and SolidWorks. A key constraint was that the total print time had to be under 6 hours, with the print time listed as exactly 6 hours at 20% infill density. This required careful design and planning to ensure the object could be completed within the time limit while still being functional and visually appealing.

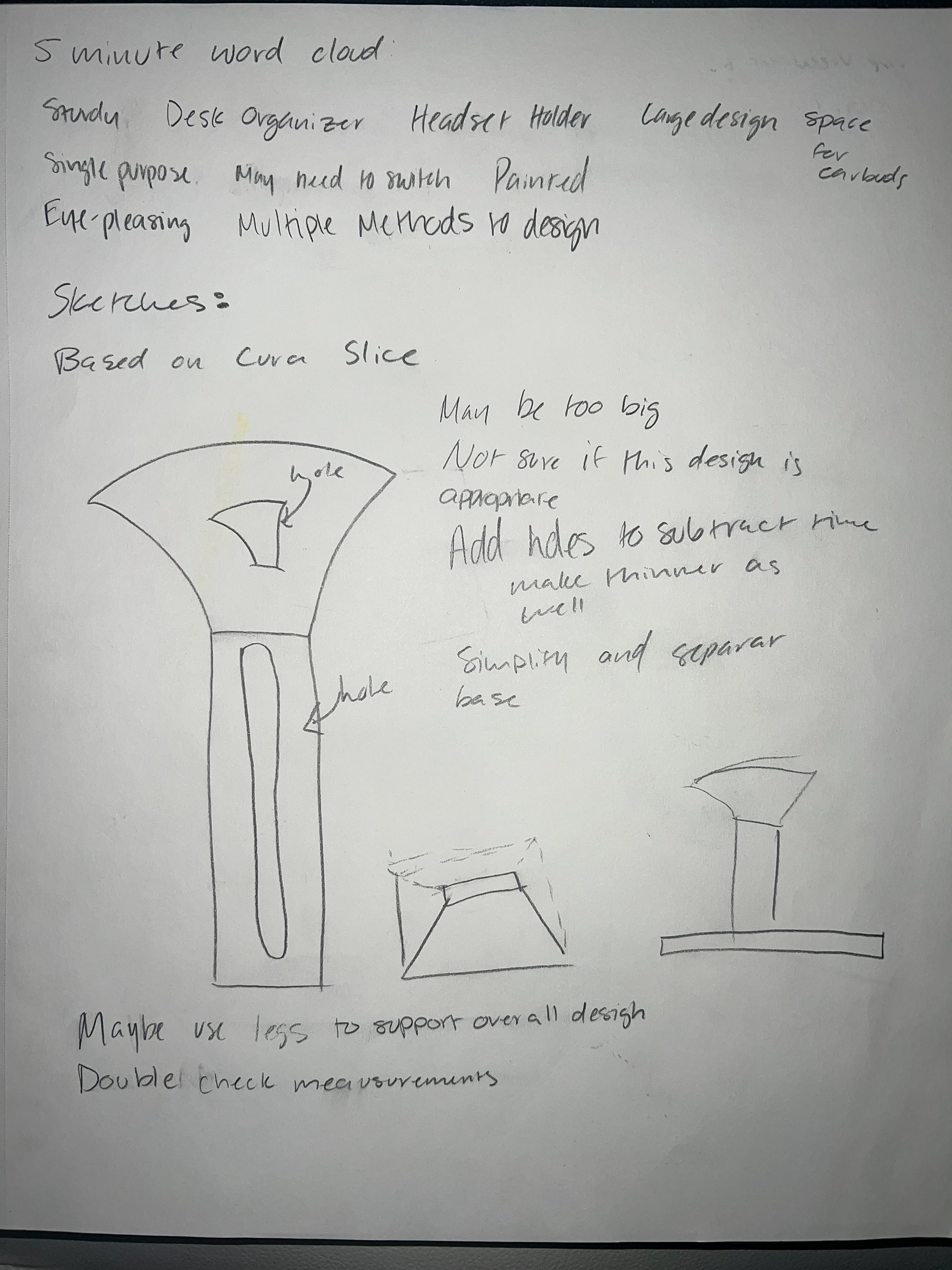

Iterative Design and Software Modeling

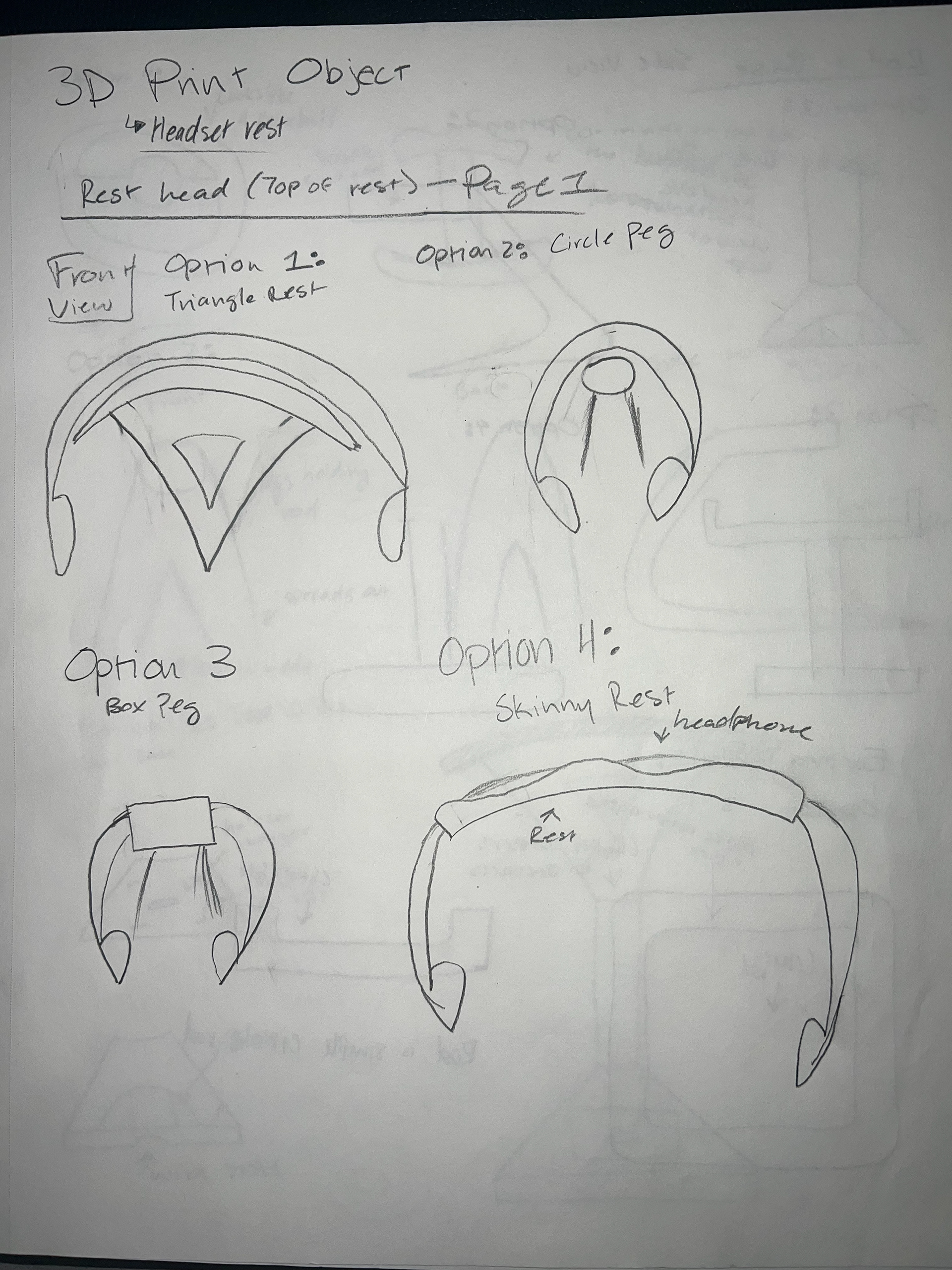

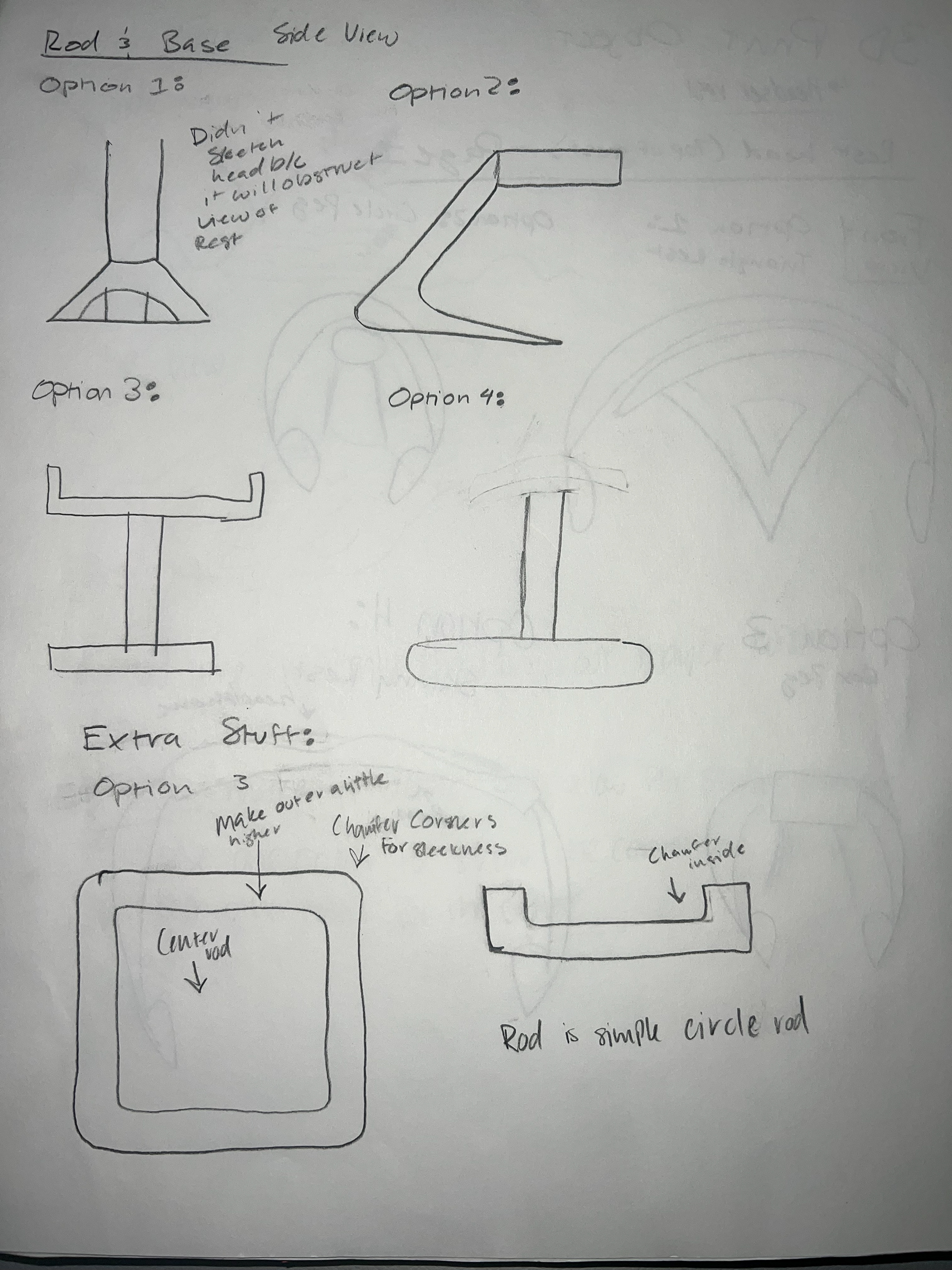

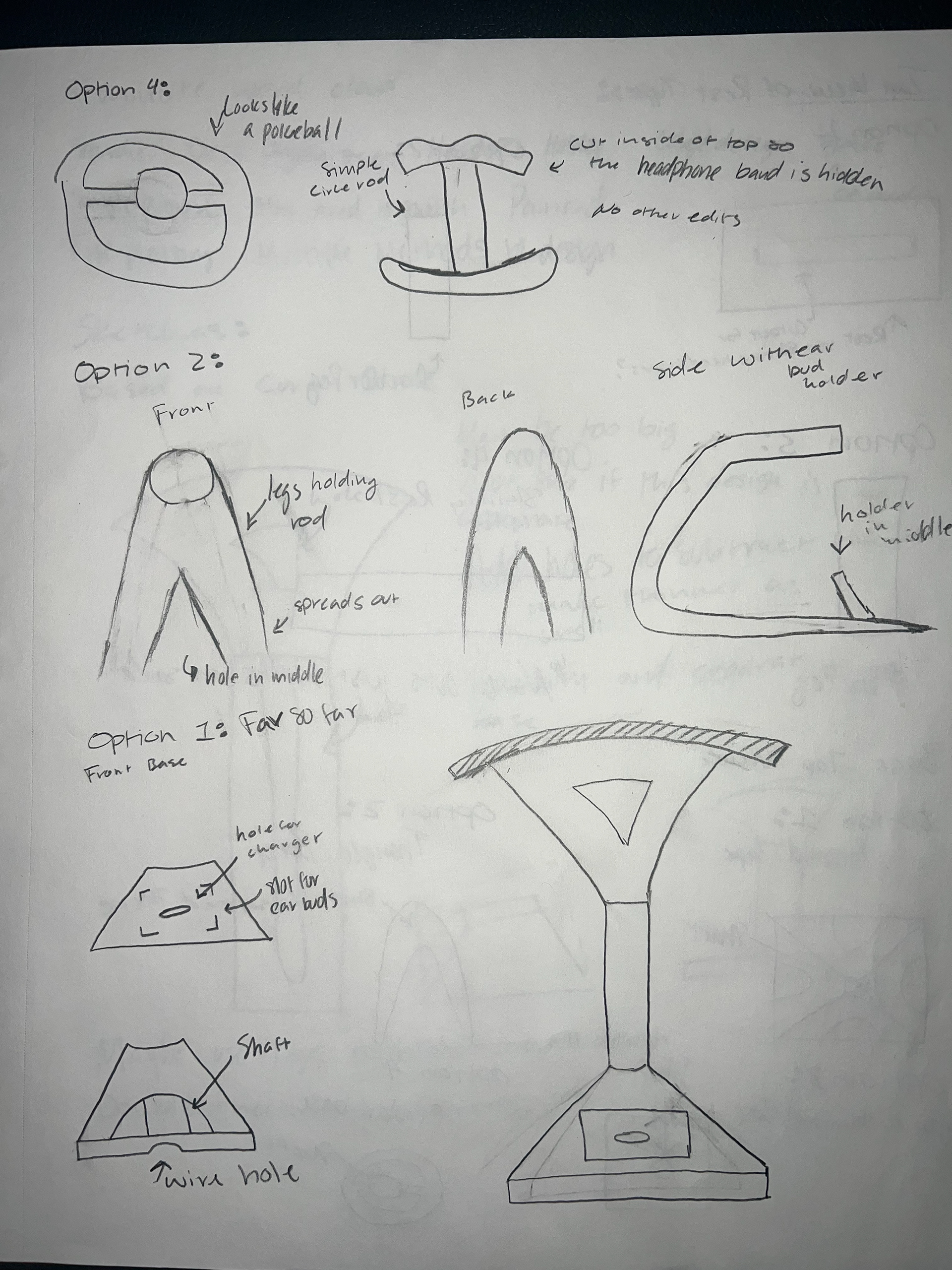

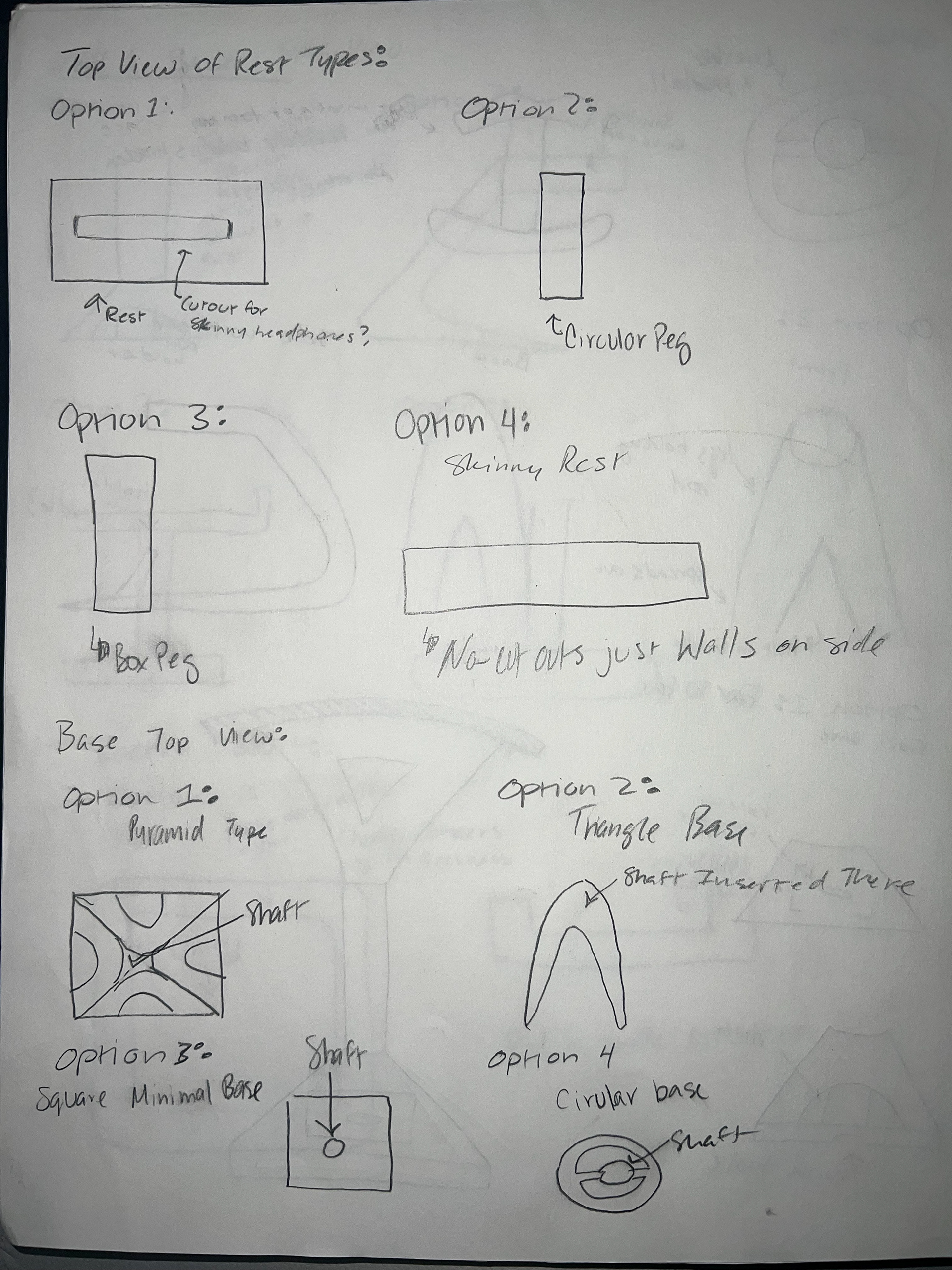

I began by brainstorming ideas through sketches and word clouds, followed by research to refine the concept. After selecting my design, I modeled it first in SolidWorks, transferring to Rhino 7 for final detailing. The real challenge came when I had to continuously tweak the design to meet the 6-hour print requirement. I had to dive deep into Cura slicing software to adjust variables like infill density, supports, and layer height, ensuring the design would print quickly without compromising structural integrity. I went through several iterations of the design, modifying features such as thickness and geometry to achieve the right balance between print time and function.

The first print attempt failed due to the PLA plastic not adhering to the glass bed. This required an additional print after correcting the bed adhesion. Once I addressed the bed adhesion issue, I continued refining the model and slicing parameters. Through careful adjustments and a deeper understanding of the slicing software, I eventually achieved the necessary print time while keeping the design intact.

Functional Design and Positive Feedback

The final product not only met the time constraints but also performed as intended. My professor and peers complimented the aesthetic qualities of the design, particularly the "airy" feel that was achieved through the structure. The project was recognized for its engineering and design balance, showing both form and function. This project taught me valuable lessons in 3D printing technology, from modeling to printer setup and G-code generation, enhancing my skills in both design and execution.

Supplementary Images Showing Design Process