Robot Tooling & Assistive Fixtures for Manufacturing Automation

The collection on this page represents some of my work on the robot integration project at Nuvera Fuel Cells. The image that you see on the left is the second to final prototype prior to the team demonstration where we demonstrated the robot capabilities regarding manufacturing and automation.

Automating Material Staging for Assembly

As part of my work at Nuvera Fuel Cells, I contributed to a robotics integration project aimed at improving material staging and sorting processes within the facility. The manual preparation of material bins for automated assembly was labor-intensive and prone to inconsistencies due to damages done to materials because of mishandling and human error. Workers had to repeatedly handle and sort components, leading to inefficiencies along the assembly line.

The challenge was to design an adaptable robot tooling system that could efficiently grasp, transport, and organize various materials while maintaining precision and repeatability in placement. The project aimed to develop a solution that would optimize workflow, minimize manual intervention, and ensure seamless integration into the existing manufacturing process.

Iterative Tooling Development & Fixture Implementation

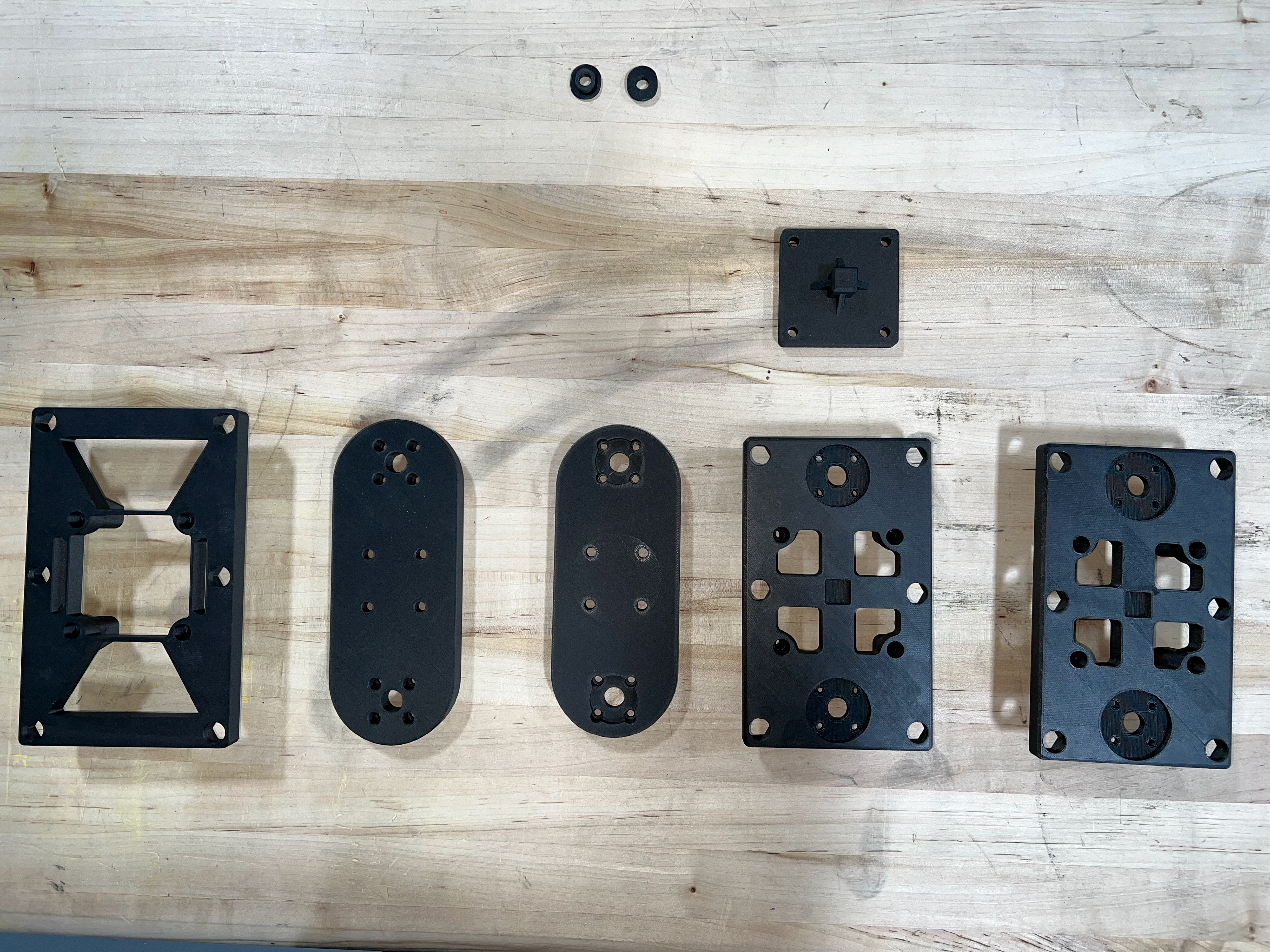

Working within the constraints of existing facility layouts, available materials, and time limitations, I utilized rapid prototyping to refine the robot’s tooling system. The robot needed to handle materials with varying porosity, which initially required different tool designs to accommodate the differences in grip and handling. Through iterative design and testing, I developed a single adaptable tool that could effectively handle all material types, eliminating the need for multiple tooling setups and reducing complexity.

During testing, we encountered an issue where slight shifts in table positioning caused misalignment in material placement, leading to inconsistent robot performance. To address this, I designed assistive fixtures using repurposed 80/20 extrusions, which kept the table at a fixed, repeatable distance from the robot. Additionally, I developed a 3D-printed calibration spike to ensure precise tool positioning, leveraging prior tolerance studies to achieve a secure press-fit design.

Throughout the process, I worked with CAD software for design, 3D printing for prototyping, and hands-on testing with the robot system to validate each iteration. These solutions ensured that the robot could reliably stage and sort materials without the need for constant re-calibration or manual intervention.

Top View

Side View

Increased Efficiency, Precision, and Automation Potential

The final tooling design significantly reduced manual labor by eliminating the need for tool swaps. Instead, the robot could seamlessly switch between suction cups and Bernoulli gripping methods via its software-controlled air supply lines. Additionally, the Keyence sensor allowed for real-time material detection, ensuring the correct handling method was applied automatically.

While the robot's cycle time was comparable to that of a manual worker, it introduced key advantages: less material wear and tear, improved consistency, and reduced operator fatigue. The 3D-printed calibration spike streamlined the robot calibration process by eliminating human error—operators no longer had to approximate the position three times from different directions. This led to more precise robot positioning and a faster, more reliable calibration process.

Testing demonstrated that the system achieved placement accuracy within 0.1 mm, with further refinements planned to enhance alignment precision using a camera-based system. Ultimately, the final review confirmed the solution’s feasibility and potential for broader implementation within the facility.